6 Reasons Why Open Cell Polyurethane Foam Is Ideal for RF Absorbers

6 Reasons Why Open Cell Polyurethane Foam Is Ideal for RF Absorbers

Polyurethane foam is gaining recognition as a top choice for RF absorbers due to its exceptional properties that enhance the accuracy and efficiency of testing environments. This article highlights the key reasons why open cell polyurethane foam is the perfect material for RF absorbers, emphasizing its absorption efficiency, cost-effectiveness, flexibility, and durability in various testing environments.

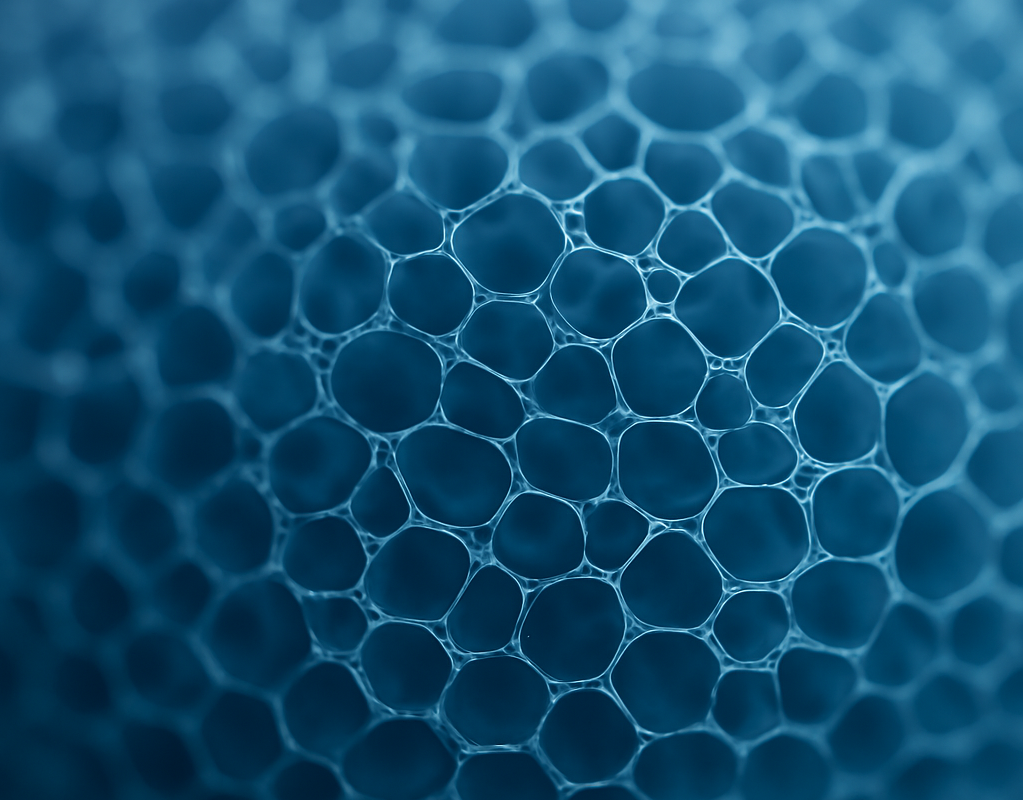

Definition and Characteristics of Polyurethane Foam

Open cell polyurethane foam is a type of foam characterized by its open, interconnected cell structure. Unlike closed-cell foams, which have tightly packed cells that trap air, open cell foams have a more porous structure, allowing air and other gases to pass through. This makes open cell foam an ideal material for absorbing RF (radio frequency) energy, as the foam's unique structure helps dissipate electromagnetic waves by converting them into heat.

Compared to closed-cell polyurethane foam, which is more rigid and impermeable, open cell foam has such advantages:

-

Lightness: Easier to handle and install in testing environments.

-

Flexibility: Can be shaped and molded to fit various configurations.

-

Superior Absorption: Effectively absorbs RF energy and minimizes reflections.

-

Enhanced Performance: Contributes to more accurate and reliable testing results.

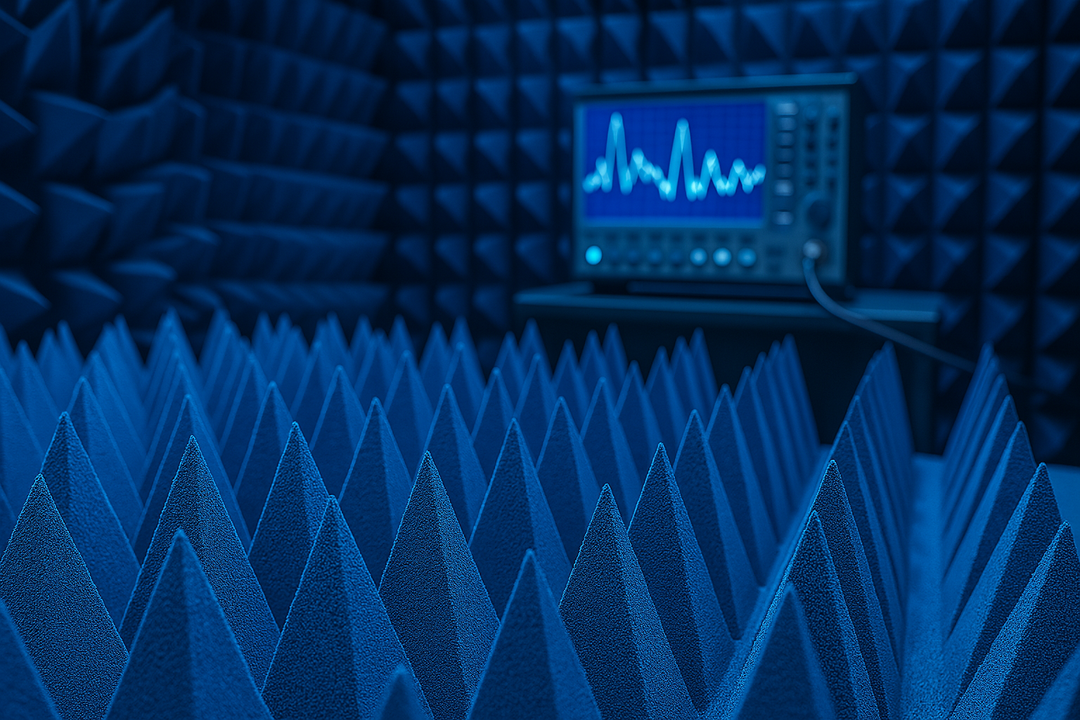

These characteristics make it especially valuable in anechoic chambers and other RF testing environments, where minimizing reflection and interference is critical.

RF absorbers play a pivotal role in preventing electromagnetic interference (EMI) and improving the quality of signals by absorbing unwanted waves. This is essential in testing environments where accuracy is paramount, such as in the development and certification of electronic devices, antennas, and communication systems. Materials like open-cell polyurethane foam contribute significantly to enhancing the performance of RF absorbers, ensuring precise measurements and reliable results.

Why Open Cell Polyurethane Foam is Good for RF Absorbers

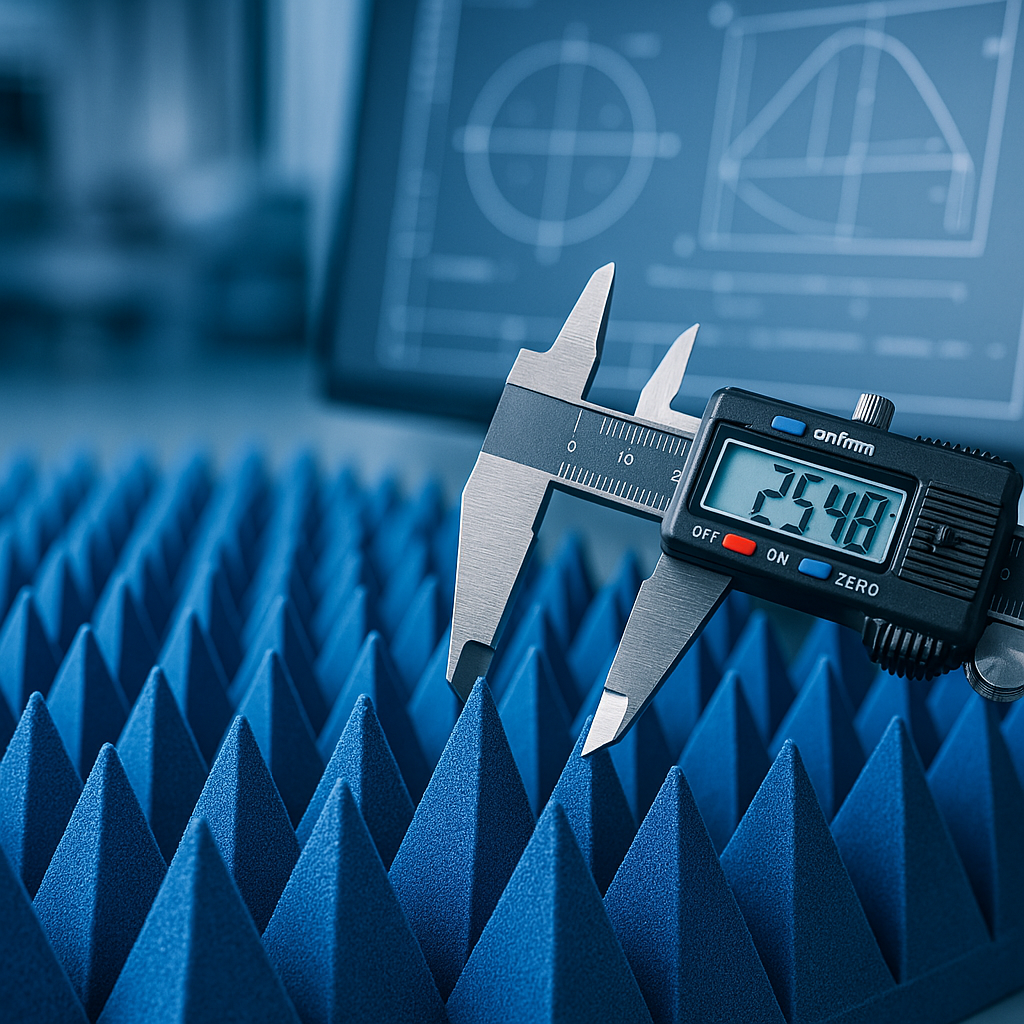

1. Excellent Absorption of Electromagnetic Waves

One of the standout features of polyurethane foam is its ability to absorb electromagnetic waves effectively. The open-cell structure allows the foam to trap RF energy, converting it into heat. This absorption efficiency makes it ideal for applications where minimizing reflection is essential, such as in RF testing and anechoic chambers.

The foam's composition and structure provide an ideal medium for absorbing various frequencies, from low to high RF signals. The material's ability to absorb RF energy without significant reflection or transmission ensures that the energy is dissipated effectively, maintaining the accuracy of the test environment.

This ability to absorb electromagnetic waves is one of the primary reasons open cell polyurethane foam is widely used in RF absorbers. It reduces the potential for signal interference and helps maintain the integrity of the tests being conducted.

2. Cost-Effectiveness and Accessibility

When it comes to manufacturing and sourcing materials for RF absorbers, cost is always a consideration. Polyurethane foam is an affordable material that offers excellent performance without a high price tag. Its relatively low cost makes it a practical choice for large-scale RF absorption projects, especially in environments where bulk material is required, such as in anechoic chambers or testing labs.

Furthermore, open cell polyurethane foam is widely available, with numerous suppliers offering different densities, thicknesses, and customizations to meet the specific needs of RF testing. This availability makes it an accessible and versatile material for various applications across industries such as telecommunications, automotive, aerospace, and electronics.

The cost-effectiveness of polyurethane foam open cell also extends to its manufacturing process. The material is easy to produce and can be molded into various shapes and sizes, which adds to its flexibility in design and application.

3. Lightweight and Flexible Properties

The open cell polyurethane foam is lightweight and flexible, making it easy to handle and install in various testing environments. Unlike heavier materials such as metals or ceramics, polyurethane foam offers a more practical solution for situations where weight and ease of installation are important considerations.

The foam's flexibility allows it to be easily shaped and adapted for different designs, whether for a custom RF absorber or use in a standard anechoic chamber. The foam can be cut, molded, and arranged to fit a variety of testing configurations, which is especially useful in environments that require specific absorber arrangements for accurate measurements.

This lightweight and flexible nature of open cell polyurethane foam also means that it can be used in a wide range of applications, from small portable devices to large-scale installations, without significantly increasing the overall weight or complexity of the system.

4. High Temperature and Humidity Resistance

Environmental conditions, such as temperature fluctuations and high humidity, can affect the performance of materials used in RF testing environments. Open cell polyurethane foam is designed to withstand these challenging conditions, ensuring its absorption properties remain effective even in harsh environments. Whether used in high-temperature conditions or locations with significant humidity, this foam maintains its structural integrity and performance over time.

This resilience is particularly important in outdoor testing environments or situations where equipment is exposed to various temperatures and humidity levels. The ability of open cell polyurethane foam insulation to perform under these conditions ensures that the absorption efficiency remains high and the test results stay accurate.

Ensuring that RF absorbers remain effective in fluctuating conditions is crucial for long-term testing and product development. It makes the temperature and humidity of polyurethane foam crucial to its suitability for RF applications.

5. Customizability and Tailored Performance

Another major advantage of open cell polyurethane foam is its ability to be customized to meet the specific needs of different RF absorption applications. The foam can be manufactured in various densities and configurations, allowing engineers to fine-tune the material to absorb specific frequencies or to meet particular absorption criteria.

Customizing the material ensures that it performs optimally in various RF testing environments, from small-scale laboratory setups to large industrial applications. This level of customizability makes polyurethane foam a versatile material, capable of adapting to the unique challenges of each RF testing scenario. It also provides manufacturers with the flexibility to optimize performance without needing to rely on multiple types of materials.

6. Eco-Friendly and Sustainable Material

In an era where sustainability is increasingly important, open cell polyurethane foam stands out for its environmental benefits. Unlike many other materials used for RF absorption, this foam is made from environmentally friendly processes. It is recyclable at the end of its life cycle.

The foam's ability to be recycled reduces its environmental impact, making it a more sustainable choice compared to other types of foam or materials that may not be as easily recyclable. Additionally, polyurethane foam is often produced using methods that minimize waste and energy consumption during the manufacturing process, further contributing to its eco-friendly appeal.

As industries continue to shift toward more sustainable practices, polyurethane foam offers a solution that balances performance, cost, and environmental responsibility.

Summarizing the Qualities of Open Cell Polyurethane Foam

Polyurethane foam is a highly effective material for RF absorbers due to its excellent absorption properties, cost-effectiveness, and versatility. Its lightweight and flexible design, combined with high temperature and humidity resistance, makes it suitable for use in various RF testing environments. Moreover, the material's ability to be customized ensures that it can meet the specific needs of different applications, making it a versatile and practical choice.

As demand for advanced RF testing grows, particularly with the advent of technologies like 5G and IoT, ongoing research and technological advancements will continue to enhance the performance and applications of open cell polyurethane foam. Innovations in foam manufacturing will further improve its absorption efficiency, cost-effectiveness, and sustainability, ensuring that it remains a key material in RF testing for years.

In summary, polyurethane foam offers numerous advantages for RF absorbers, making it the ideal material for ensuring the accuracy and reliability of RF testing environments. Whether for small-scale applications or large industrial setups, its performance, cost-effectiveness, and flexibility make it a valuable asset in modern communication systems and electronic product development.

Looking for high-quality polyurethane foam RF absorbers? Browse our selection designed for optimal absorption performance across various frequencies and applications.

This article was written by the RF experts at dB Absorber, specializing in high-performance broadband absorbers for RF and microwave applications.