About RF Absorbers

About RF Absorbers

What are Pyramidal Anechoic Absorbers made from?

Pyramidal anechoic absorbers are typically made from a foundation of open-cell polyurethane foam that is volumetrically loaded with carbon and fire retardants. This material is selected for its dielectric properties, which are well-suited for ultra-broadband performance in RF and microwave applications. The foam is shaped into a pyramid or cone shape, which helps to absorb and dissipate incoming RF energy, reducing reflections and improving the accuracy of measurement and testing.

How are Anechoic Chambers constructed?

Anechoic chambers are specialized rooms that are designed to block or absorb electromagnetic waves, including radio waves and microwaves, in order to create a "quiet" electromagnetic environment for testing and measurement. These chambers are typically constructed using a combination of materials and techniques that are designed to reflect, absorb, or otherwise attenuate incoming electromagnetic waves.

The walls, ceiling, and floor of an anechoic chamber are typically lined with RF absorber material, such as pyramidal or wedge-shaped absorbers made from foam and other dielectric materials. This material is carefully selected and positioned to create a gradient of reflection and absorption, with the walls and ceiling designed to absorb most of the incoming electromagnetic energy and the floor designed to reflect it. The absorber material is typically covered with a layer of conductive material, such as copper or aluminum, to improve its performance.

In addition to the absorber material, anechoic chambers may also incorporate other design elements to further reduce reflections and improve the "quietness" of the environment. These may include specialized door and window seals to prevent electromagnetic waves from entering or escaping the chamber, as well as carefully designed ventilation systems to prevent RF energy from entering or escaping through the air ducts.

Overall, the design and construction of an anechoic chamber is a complex process that involves careful consideration of a variety of factors, including the frequency range of the electromagnetic waves to be measured, the size and shape of the chamber, and the specific requirements of the measurement or testing application.

What types of companies use anechoic absorbers?

Anechoic absorbers are used by a variety of companies and organizations that need to measure or test electromagnetic devices or systems. This may include manufacturers of electronic components and systems, such as antennas, radars, and satellite communications equipment, as well as government agencies and research institutions that conduct testing and evaluation of electromagnetic devices.

Anechoic absorbers are also used by companies that provide testing and certification services for electromagnetic devices, such as telecommunications equipment and automotive components. These companies typically have large anechoic chambers that are used to test the performance and compliance of a wide range of devices, and they may use a variety of absorber materials and configurations to create the desired test environment.

Overall, anechoic absorbers are an essential tool for companies and organizations that need to accurately measure or test the performance of electromagnetic devices, and they are an important part of many different industries and applications.

How are are anechoic absorbers tested?

Anechoic absorbers are typically tested using specialized equipment and procedures that are designed to measure their performance and effectiveness in reducing reflections and dissipating electromagnetic energy. These tests may be performed in an anechoic chamber or other controlled environment, and they typically involve the use of specialized equipment, such as antenna systems, signal generators, and spectrum analyzers, to generate and measure the RF or microwave signals that are used to evaluate the absorbers.

One common test method for anechoic absorbers is the "reflection coefficient" measurement, which is used to evaluate the absorber's ability to reduce reflections from a given surface. This measurement is typically performed using an antenna system that is positioned at a fixed distance from the absorber material, and the resulting reflections are measured and compared to the incoming signal to determine the absorber's performance.

Another important test for anechoic absorbers is the "absorption coefficient" measurement, which is used to evaluate the absorber's ability to dissipate electromagnetic energy. This measurement is typically performed using a similar setup to the reflection coefficient measurement, but the absorber material is placed at different distances from the antenna system to evaluate its performance at different frequencies and angles of incidence.

Overall, the testing of anechoic absorbers is a complex and specialized process that involves the use of specialized equipment and procedures to evaluate the performance of the absorber material and ensure that it meets the requirements of the application.

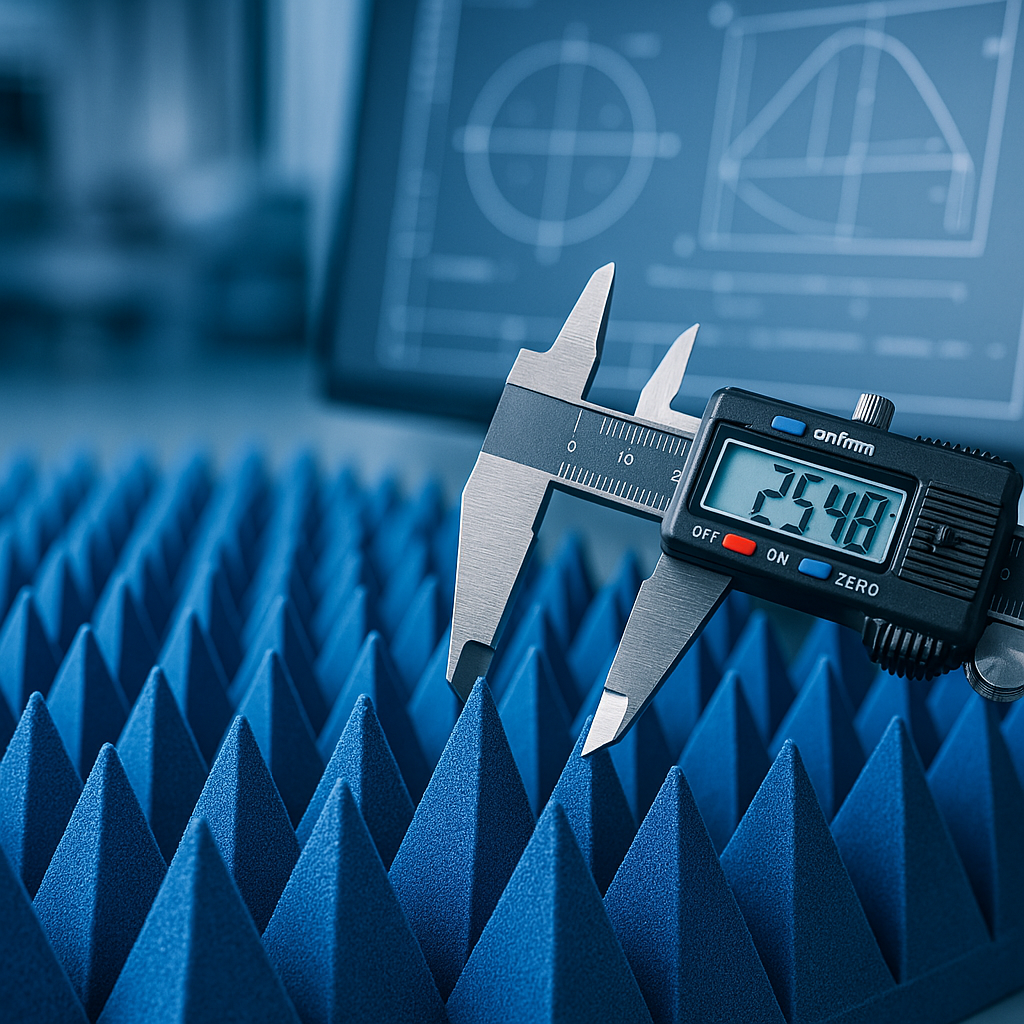

How do I decide the pyramid height for my anechoic absorbers?

The pyramid height of an anechoic absorber is an important factor in determining its performance and effectiveness in reducing reflections and dissipating electromagnetic energy. In general, the pyramid height should be selected based on the specific requirements of the application and the characteristics of the electromagnetic signals that will be incident on the absorber material.

One important consideration when selecting the pyramid height of an anechoic absorber is the frequency range of the signals that will be incident on the absorber. In general, higher frequency signals require longer pyramid heights to be effectively absorbed, while lower frequency signals can be absorbed by shorter pyramid heights. As a result, the pyramid height should be selected based on the frequency range of the signals that will be incident on the absorber material.

Another important factor in determining the pyramid height of an anechoic absorber is the angle of incidence of the incoming signals. In general, absorbers with shorter pyramid heights are more effective at absorbing signals that are incident at low angles, while absorbers with taller pyramid heights are more effective at absorbing signals that are incident at high angles. As a result, the pyramid height should be selected based on the expected angle of incidence of the incoming signals.

Overall, the selection of the pyramid height for an anechoic absorber is a complex process that involves careful consideration of a variety of factors, including the frequency range and angle of incidence of the incoming signals, as well as the specific requirements of the application. It is recommended that you consult with a professional in the field or a manufacturer of anechoic absorbers to determine the appropriate pyramid height for your application.

How long do anechoic absorbers last?

The lifespan of an anechoic absorber will depend on a variety of factors, including the quality of the absorber material, the environment in which it is used, and the frequency and intensity of the incoming electromagnetic signals. In general, high-quality absorbers made from durable materials and used in controlled environments can last for many years, while absorbers that are exposed to harsh conditions or high levels of electromagnetic energy may have a shorter lifespan.

It is also important to note that the performance of an anechoic absorber may degrade over time, even if the absorber material itself is still in good condition. This can occur due to factors such as compression of the absorber material, contamination of the surface of the absorber, or changes in the electromagnetic environment in which the absorber is used. As a result, it is important to regularly evaluate the performance of anechoic absorbers and replace them if necessary to ensure that they continue to provide the desired level of performance.

Overall, the lifespan of an anechoic absorber can vary widely depending on the specific conditions of use and the quality of the absorber material. It is recommended that you consult with the manufacturer or a professional in the field to determine the expected lifespan of your absorbers and plan for regular evaluation and replacement as needed.

Why do anechoic absorbers degrade over time?

Anechoic absorbers may degrade over time due to a variety of factors, including physical wear and tear, contamination, and changes in the electromagnetic environment in which the absorbers are used.

Physical wear and tear can cause anechoic absorbers to degrade over time. For example, the absorber material may become compressed or damaged due to repeated exposure to high levels of electromagnetic energy or physical impact. This can affect the absorber's ability to effectively reduce reflections and dissipate incoming electromagnetic energy, reducing its performance over time.

Contamination of the surface of the absorber can also cause degradation over time. For example, dust, dirt, or other debris may accumulate on the absorber material, reducing its effectiveness by creating additional reflections or reducing its ability to dissipate incoming electromagnetic energy.

Changes in the electromagnetic environment in which the absorber is used can also cause degradation over time. For example, if the frequency range or intensity of the incoming electromagnetic signals changes, the absorber may no longer be optimally matched to the new conditions, reducing its effectiveness.

Overall, anechoic absorbers may degrade over time due to a variety of factors, and it is important to regularly evaluate their performance and replace them if necessary to ensure that they continue to provide the desired level of performance.

What is the recommended adhesive for anechoic absorbers?

The recommended adhesive for anechoic absorbers will depend on the specific type of absorber material and the application in which it will be used. In general, it is best to consult with the manufacturer of the absorber material or a professional in the field to determine the appropriate adhesive for your specific application.

Some commonly used adhesives for anechoic absorbers include pressure-sensitive adhesives, such as acrylic or rubber-based adhesives, which are easy to apply and provide good adhesion to a variety of surfaces. These adhesives are often used for applications where the absorbers will be temporarily or semi-permanently attached to a surface, such as for testing or measurement purposes.

Other adhesives, such as epoxy or polyurethane adhesives, may be more suitable for applications where the absorbers will be permanently attached to a surface, such as in the lining of an anechoic chamber. These adhesives provide strong adhesion and durability, but they may require specialized application equipment and techniques, and they may not be suitable for all types of absorber materials or surfaces.

Overall, it is important to carefully consider the specific requirements of your application and consult with a professional to determine the appropriate adhesive for your anechoic absorbers.

What types of absorbers are used in anechoic chambers?

Anechoic chambers are specialized rooms that are designed to block or absorb electromagnetic waves, including radio waves and microwaves, in order to create a "quiet" electromagnetic environment for testing and measurement. To achieve this, anechoic chambers are typically lined with RF absorber material, which is carefully selected and positioned to create a gradient of reflection and absorption.

A variety of absorber materials and configurations are used in anechoic chambers, depending on the specific requirements of the application and the characteristics of the electromagnetic signals that will be incident on the absorbers. Some common types of absorbers used in anechoic chambers include:

- Pyramidal absorbers: Pyramidal absorbers are one of the most common types of absorbers used in anechoic chambers. These absorbers are made from foam or other dielectric materials that are shaped into pyramids or cones, with the pyramids typically arranged in a regular pattern on the walls, ceiling, and floor of the chamber. Pyramidal absorbers are effective at absorbing a wide range of frequencies and angles of incidence, making them a versatile choice for many applications.

- Wedge absorbers: Wedge absorbers are similar to pyramidal absorbers, but they are shaped into wedges or trapezoids rather than pyramids. These absorbers are typically used in anechoic chambers to provide a gradient of reflection and absorption, with the wedges arranged in a graduated pattern to create a smooth transition from reflection to absorption. Wedge absorbers are effective at absorbing a wide range of frequencies and angles of incidence, but they may be more specialized than pyramidal absorbers and may not be suitable for all applications.

- Convoluted surface absorbers: Convoluted surface absorbers are a type of absorber

Why do anechoic absorbers use pyramids?

Anechoic absorbers are typically shaped into pyramids or cones in order to effectively reduce reflections and dissipate electromagnetic energy. The pyramid shape is effective at absorbing electromagnetic waves because it creates a gradient of reflection and absorption, with the apex of the pyramid absorbing the highest frequencies and the base of the pyramid absorbing the lowest frequencies.

The pyramid shape is also effective at absorbing electromagnetic waves at different angles of incidence, with the sides of the pyramid absorbing signals that are incident at low angles, and the apex of the pyramid absorbing signals that are incident at high angles. This makes pyramidal absorbers a versatile choice for many applications, as they can effectively absorb a wide range of frequencies and angles of incidence.

In addition to their performance characteristics, pyramidal absorbers are also relatively easy to manufacture and install, making them a practical choice for many applications. The regular pyramid shape allows for efficient packing and arrangement of the absorbers in an anechoic chamber, and the pyramid shape is relatively simple to cut and shape from absorber materials, such as foam or fiberglass.

Overall, the use of pyramids in anechoic absorbers is based on their effectiveness at reducing reflections and dissipating electromagnetic energy, as well as their practicality and ease of manufacture and installation.