Why is a Microwave Absorber Essential in Communication System Testing?

Why is a Microwave Absorber Essential in Communication System Testing?

In communication system testing, ensuring the integrity of signals and minimizing interference is essential. One of the key tools for achieving this is the microwave absorber. It plays a vital role in controlling microwave signals, reducing unwanted reflections, and ensuring testing environments are as accurate as possible. This article will explore the importance of wave absorbers in communication system testing, explaining how they work, the materials used, and their applications in ensuring the reliability of communication technologies.

Definition of a Microwave Absorber and Its Purpose

A microwave absorber is a material designed to absorb electromagnetic waves, particularly those in the microwave frequency range. Its primary purpose in testing environments is to prevent unwanted reflection and interference of microwave signals, ensuring test results are accurate and reliable. Without proper microwave absorption, signals can bounce off walls, test equipment, and other surfaces, leading to inaccurate readings, distortion, and performance issues that could affect the development and testing of communication systems.

In communication system testing, it is crucial to ensure that measured signals are not contaminated by external factors. Accurate testing allows engineers and technicians to assess the performance of communication technologies, such as antennas, signal generators, and receivers. By controlling microwave signals and minimizing interference, wave absorbers help to ensure that communication systems are optimized for performance and signal integrity.

How Microwave Absorber Works

The Principle Behind Microwave Absorption

The fundamental principle behind a microwave absorber is its ability to convert electromagnetic energy into heat, effectively dissipating the microwave energy rather than allowing it to reflect into the testing environment. This process involves the interaction between the microwave energy and the material's structure. As the microwave energy encounters the material, it induces currents that generate heat, which is absorbed by the material, thereby preventing reflection and interference.

The effectiveness of this process depends largely on the material's properties, such as its permeability, conductivity, and dielectric constant. These factors influence how well the material can absorb microwave energy across a wide frequency range.

The Mechanism of Absorption

In more detail, microwave absorber works by using either conductive or absorptive properties. Conductive materials reflect the microwave energy away from the device being tested, while absorptive materials, like foam, absorb the energy and convert it into heat. In the case of absorptive foam, the material's open-cell structure plays a significant role in its ability to absorb microwave energy. The foam's structure creates numerous paths that the microwave energy must travel through, allowing it to dissipate effectively.

When absorptive foam is used in testing, it minimizes unwanted reflections and ensures only the direct signal is measured, enhancing the accuracy of the testing process. This is particularly critical in high-frequency tests, where precision is essential.

The Role of Microwave Absorber in Communication System Testing

Minimizing Interference in RF and Microwave Systems

One of the most important roles of microwave absorber in communication system testing is to reduce electromagnetic interference (EMI). EMI can come from various sources, such as other nearby electronic devices or reflections from walls and other surfaces within a testing environment. If not properly controlled, this interference can distort the test signals, making it difficult to get accurate measurements.

In testing environments, absorbers help to create a "quiet" environment by absorbing the unwanted signals, ensuring that the only signals that are measured are those directly emanating from the source being tested. By minimizing interference, wave absorbers ensure that the test results are reliable and reflect the true performance of the communication system.

Ensuring Accurate Signal Measurement

Accurate signal measurement is critical in the design and testing of communication systems. Microwave absorber helps to ensure that the signals being tested are not distorted by external factors, allowing engineers to measure key parameters like signal strength, clarity, and integrity. In anechoic chambers, such absorbers are used extensively to create an isolated environment free of interference, where signals can be tested in a controlled setting.

Without microwave attenuation, it would be difficult to obtain accurate readings, as any reflection or interference could skew the data. These absorbers help maintain signal clarity, ensuring that engineers can identify potential problems in the communication system and optimize its performance before deployment.

Testing in Anechoic Chambers

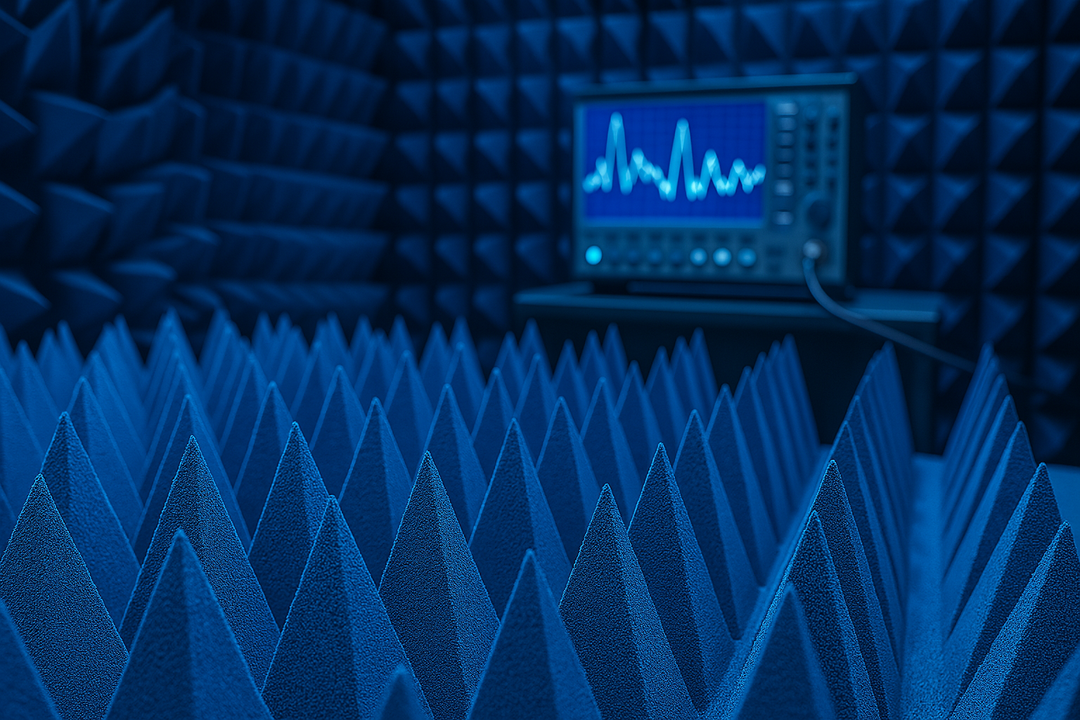

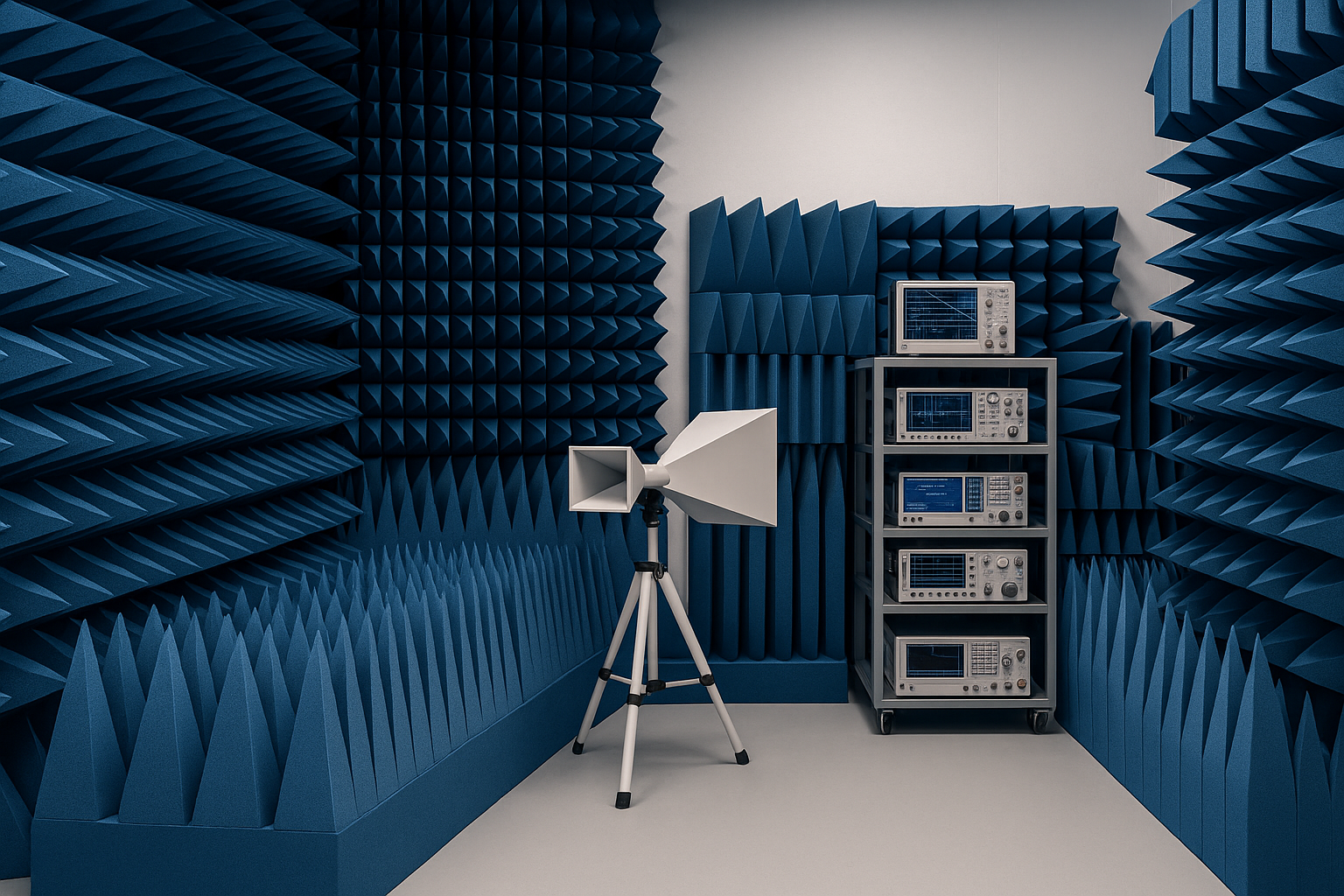

Anechoic chambers are specialized rooms designed to create an environment where all external signals are absorbed, leaving only the direct signal from the device being tested. These chambers rely heavily on absorbers to achieve their purpose. The walls, floors, and ceiling of an anechoic chamber are lined with materials that absorb electromagnetic waves, including microwave absorber foam. This setup helps ensure the testing environment is completely free from unwanted reflections and external interference, providing a "clean" space for signal testing.

The use of wave absorbers in anechoic chambers is crucial in fields such as antenna testing, where precision and accuracy are paramount. Without proper absorption, the performance of antennas and other RF components would be impossible to measure accurately.

Materials Used in Microwave Absorbers

Materials That Absorb Microwaves

Several materials can be used for microwave absorption, each with specific properties suited for different types of testing. Common materials include:

- Carbon-loaded foam

- Ferrite materials

- Specialized composite materials

Microwave absorber foam is one of the most widely used options due to its ability to absorb a broad spectrum of frequencies and its installation flexibility. Foam-based absorbers are often favored for their ability to absorb energy effectively across a wide range of frequencies. These materials are lightweight, cost-effective, and easy to install, making them ideal for small-scale and large-scale testing environments.

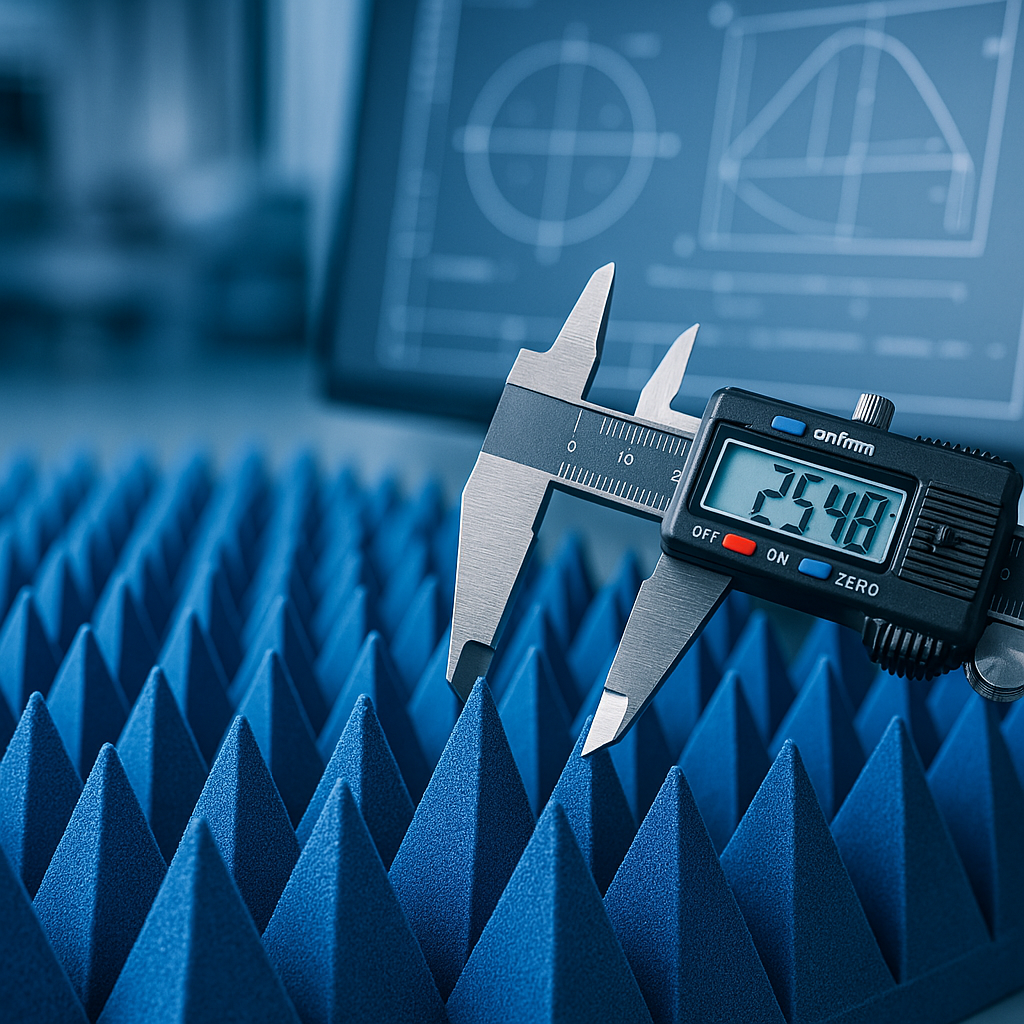

The choice of absorptive foam depends on several factors, including the frequency range of the signals to be absorbed, the size of the testing environment, and the level of absorption required. Customizable foam options are available for specific needs, ensuring the testing environment is optimized for performance.

Applications of Microwave Absorber in Communication Systems

Testing Antennas and Signal Integrity

One of the primary applications of wave absorber is testing antennas and ensuring signal integrity. In antenna testing, it is crucial to measure how the antenna performs without any external interference or reflection. By using such absorbers, engineers can ensure that only the direct signal is measured, allowing them to assess the true performance of the antenna.

Accurate antenna testing is essential for ensuring that communication systems are reliable and capable of transmitting clear signals over long distances. By minimizing reflection and interference, wave absorbers play a key role in this process.

Simulating Real-World Environments

Microwave absorber is used in simulating real-world conditions in testing environments. For example, in wireless communication testing, it is important to replicate the conditions under which a device will operate in the field. This includes accounting for signal reflection, interference, and other environmental factors. By using absorbers in test setups, engineers can simulate the real-world behavior of communication systems, providing valuable insights into their performance under various conditions.

Reducing Electromagnetic Interference

In addition to its role in testing, microwave attenuation material helps reduce electromagnetic interference (EMI) in communication systems. This is particularly important in environments where multiple devices are operating simultaneously, such as in communication networks or data centers. By absorbing unwanted microwave energy, wave absorbers help maintain the integrity of signals and prevent interference from affecting the performance of other devices.

Challenges in Using Microwave Absorber

Proper Selection of Absorber Material

Choosing the right microwave absorber material for a particular application can be challenging. The material must be carefully selected based on the frequency range, the type of interference to be mitigated, and the specific requirements of the testing environment. Not all materials perform equally well across all frequencies, and some may need to be customized to meet the needs of a particular device or system.

Handling and Installation of Absorbers

Another challenge is the handling and installation of wave absorbers. These materials must be properly arranged to effectively absorb microwave energy without causing other issues, such as blocking ventilation or interfering with other test equipment. Ensuring that absorptive foam is installed correctly is essential for achieving optimal performance.

Ensuring Longevity and Performance Over Time

Over time, absorptive material can degrade due to wear, environmental exposure, and physical stress. Ensuring the longevity and continued performance of these materials is essential for maintaining the effectiveness of testing environments. Regular maintenance and replacement of degraded materials are necessary to ensure the test results remain accurate.

Summary

So, the microwave absorber plays an essential role in communication system testing by minimizing interference, ensuring accurate signal measurements, and simulating real-world conditions. Whether used in anechoic chambers or other RF testing environments, these materials help maintain signal integrity and improve the reliability of communication systems.

As communication technologies continue to advance, the importance of absorbers will only grow. Ongoing research and development will continue to improve the performance and cost-effectiveness of these materials, ensuring their continued relevance in the testing and development of future communication systems.

Looking for high-quality microwave absorbers for your testing facility? Browse our selection of advanced RF absorbing materials designed for communication system testing.

This article was written by the RF engineering experts at dB Absorber, specialists in high-performance microwave and RF absorbing solutions.