The Importance of Electromagnetic Shielding in Protecting Electronics

The Importance of Electromagnetic Shielding in Protecting Electronics

Electromagnetic shielding is a key technology used to protect sensitive electronics from interference that can compromise their performance. This article explores the role of EM shielding, discusses the materials and techniques used, and examines its applications across various industries. By understanding the importance of proper shielding, you can ensure the longevity, performance, and reliability of electronic devices in an increasingly connected world.

What is Electromagnetic Shielding and How It Works

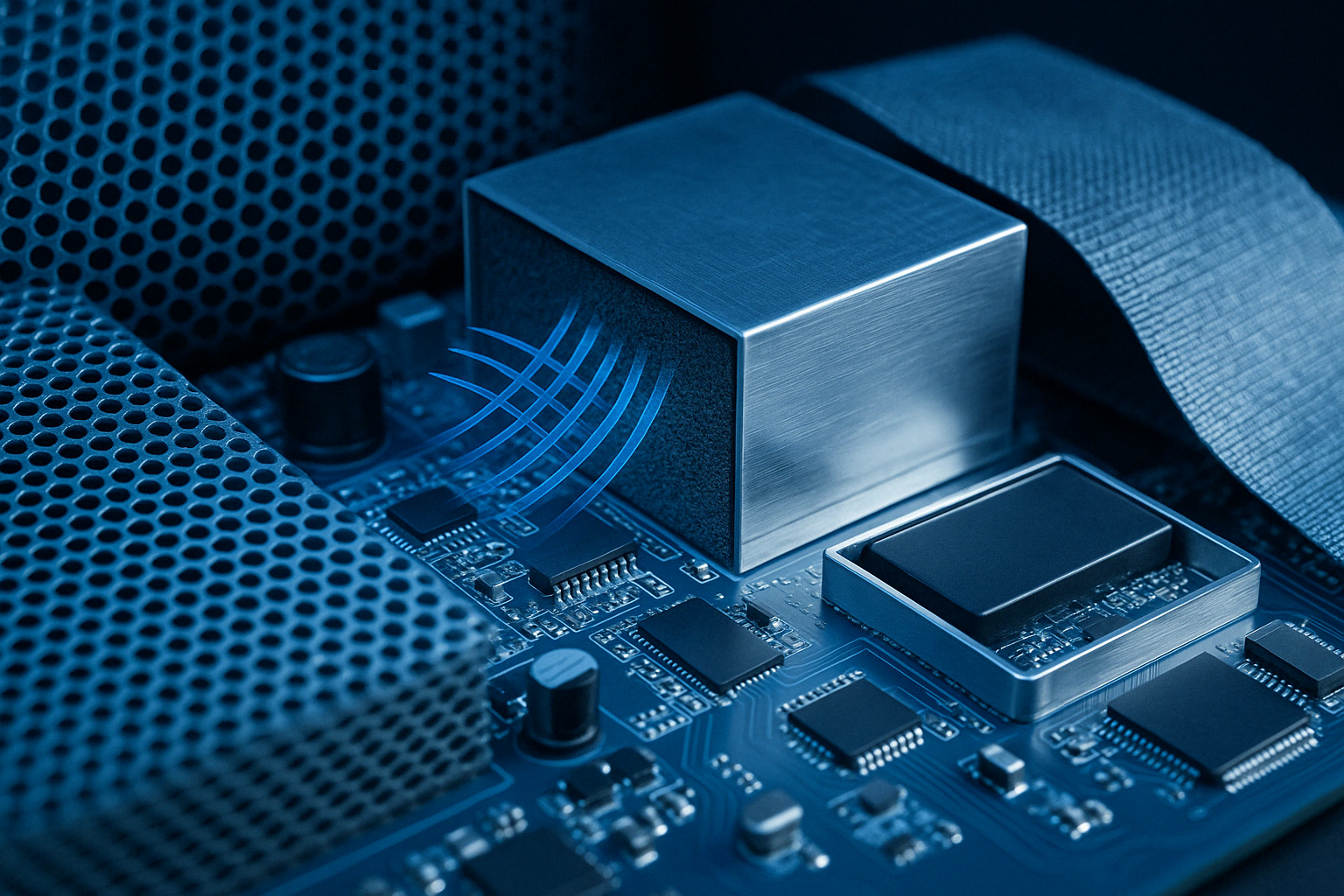

Electromagnetic interference shielding refers to the practice of blocking or reducing electromagnetic fields from interfering with sensitive electronic components. It uses materials that can absorb or reflect electromagnetic waves, preventing them from entering the device and causing disruptions. This process helps to protect the integrity of the device's signals, preventing the degradation of performance that electromagnetic interference (EMI) could cause.

The impact of electromagnetic interference on electronic devices can be significant. EMI can cause malfunctions, data loss, and performance degradation. Over time, continuous exposure to EMI can reduce the lifespan of electronic components, leading to costly repairs or replacements. This is why the importance of EM shielding cannot be overstated, especially for devices where reliability is crucial, such as medical equipment, communication systems, and high-performance consumer electronics.

Across a variety of industries, electromagnetic shielding plays a central role in ensuring the proper functioning of electronic systems. From automotive manufacturers to telecommunications providers, companies rely heavily on effective shielding to ensure that their devices remain immune to unwanted interference.

Understanding Electromagnetic Interference

What is Electromagnetic Interference?

Electromagnetic interference (EMI) refers to the disruption caused by electromagnetic fields that interfere with the normal operation of electronic devices. EMI can come from natural and man-made sources, including radio waves, power lines, electrical devices, and environmental factors like thunderstorms.

EMI can occur when electromagnetic waves, either from external sources or within the device itself, interact with the electrical components, causing unexpected voltage or current fluctuations. This can result in erratic device behavior, malfunctioning, or data corruption. The nature of these disturbances varies widely depending on the frequency and intensity of the electromagnetic waves, making it essential to address EMI with effective shielding materials.

Sources of Electromagnetic Interference

Common sources of electromagnetic interference include various electrical and electronic devices that emit electromagnetic waves. These devices include everything from mobile phones and Wi-Fi routers to high-voltage power lines and industrial machinery. Even the simplest household appliances, like microwave ovens and fluorescent lights, can be sources of interference.

In addition to human-made sources, natural phenomena such as solar flares or lightning can generate electromagnetic disturbances. These types of interference can be particularly challenging, as they are not always predictable, making effective shielding more important for sensitive electronics.

How Electromagnetic Shielding Protects Electronics

The Role of Conductive and Absorptive Materials

Electromagnetic shielding materials are typically categorized into two types: conductive and absorptive. Conductive materials, like metals, work by reflecting electromagnetic waves away from the shielded device. These materials can include copper, aluminum, and steel, which are known for their high conductivity. Reflective shielding is highly effective at blocking high-frequency signals and is commonly used in shielding enclosures, cables, and casings.

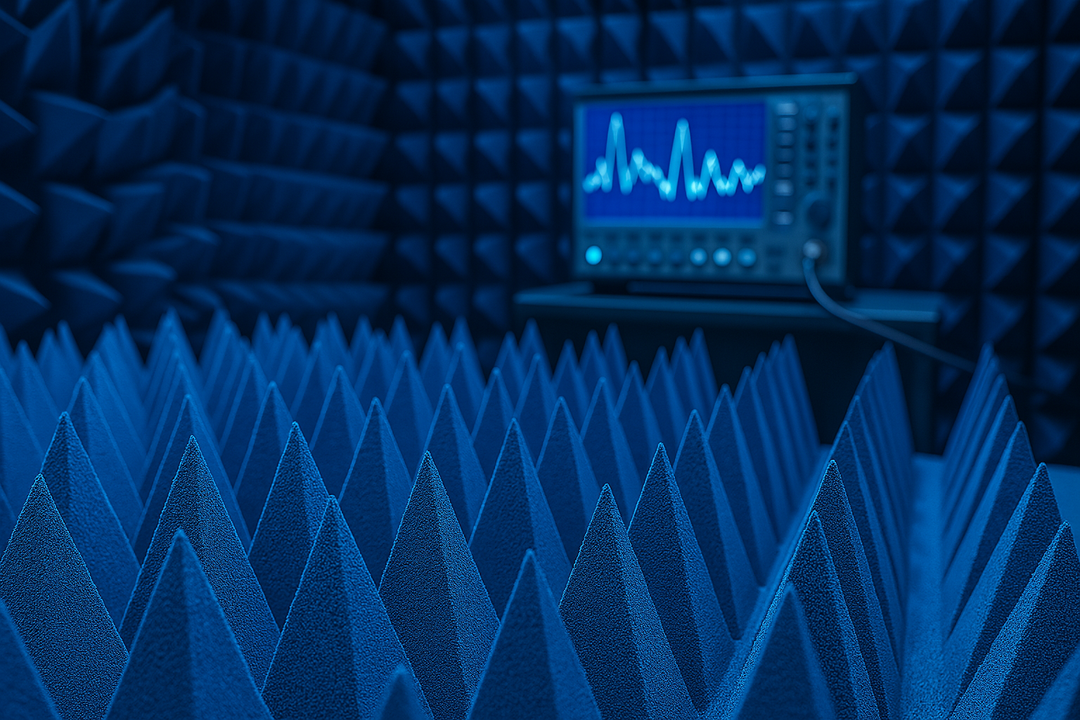

Absorptive materials, on the other hand, absorb the incoming electromagnetic energy and convert it into heat, preventing it from affecting the electronic components. Common absorptive materials include various foams, fabrics, and composites specially designed to absorb electromagnetic waves. Electromagnetic field shielding typically combines both types of materials, as this dual approach allows for greater flexibility in addressing different types of interference.

By employing these shielding materials, electronics are protected from external EMI, ensuring they can function without degradation. This is particularly important in testing environments, where accurate measurements are critical, as well as in everyday consumer devices that rely on uninterrupted signals for optimal performance.

Common Materials Used for Shielding

The materials used in electromagnetic shielding vary depending on the requirements of the specific application. Some of the most commonly used materials include:

-

Metals: Copper and aluminum are frequently used in shielding due to their excellent conductive properties.

-

Conductive fabrics: Often used for flexible shielding solutions, conductive fabrics can be applied to electronic devices or used as part of enclosures.

-

Foams and composites: These are used for absorbing electromagnetic energy, especially in areas where weight and flexibility are important.

-

Paints and coatings: Special coatings can be applied to surfaces to provide a thin, lightweight shielding option.

When choosing the right material for electromagnetic shielding, considerations such as frequency range, environmental resistance, and cost must be taken into account.

Factors to Consider When Choosing Electromagnetic Shielding Materials

Frequency Range

Different materials offer varying levels of effectiveness at different frequencies. For high-frequency applications, such as those in telecommunications or data transmission, materials that offer excellent reflection and absorption at higher frequencies are essential. In contrast, low-frequency interference may require materials with different properties. Selecting the best material for electromagnetic shielding involves ensuring that the chosen material performs well across the relevant frequency ranges of the system being protected.

Material Thickness and Weight

The thickness and weight of the shielding material also play a significant role in its effectiveness. Thicker materials may provide better shielding, but they can also increase the overall weight and size of the device. When designing for portable devices, such as mobile phones or laptops, balancing the need for effective shielding with the requirement for lightweight design is crucial.

Environmental Resistance

Shielding materials must also be resistant to environmental factors, such as moisture, temperature fluctuations, and physical wear. In outdoor applications, such as in the automotive or aerospace industries, materials must be durable and capable of withstanding harsh conditions. Electromagnetic field shielding solutions must be selected with these environmental considerations in mind to ensure long-term performance.

Cost and Performance Trade-offs

As with any material selection, cost is always a factor. While some high-performance shielding materials may provide excellent protection against interference, they can be expensive. In many cases, manufacturers need to strike a balance between cost and shielding effectiveness, choosing materials that provide the best value for the intended application. The trade-off between cost and performance is often determined by the critical nature of the device's operation and its susceptibility to interference.

Applications of Electromagnetic Shielding

Consumer Electronics

Electromagnetic shielding plays a vital role in consumer electronics, including mobile phones, tablets, and laptops. These devices rely on wireless communication, which makes them particularly vulnerable to electromagnetic interference. Effective shielding ensures that they maintain reliable communication, with minimal disruption from external sources of EMI.

Medical Devices

In medical applications, the reliability of equipment is critical. Devices such as pacemakers, MRI machines, and other diagnostic equipment are highly sensitive to interference. Specialized shielding materials ensure that these devices function correctly and provide accurate readings. Shielding also protects patients from any potentially harmful effects of electromagnetic radiation.

Aerospace and Automotive Industries

In industries like aerospace and automotive, electromagnetic shielding is used to protect sensitive electronic systems from interference. This is particularly important for navigation systems, communication systems, and control electronics. The reliability of these systems is paramount, especially in critical situations such as air travel or autonomous driving.

Telecommunications

Telecommunications infrastructure, including base stations and satellites, relies heavily on electromagnetic shielding to ensure reliable performance. These systems are constantly exposed to external interference from a variety of sources, and shielding is used to protect their components from degradation or failure.

Challenges in Electromagnetic Shielding Design

Designing for Complex Devices

As technology becomes more advanced, the devices being designed are becoming more complex. EM shielding solutions must keep up with this complexity. Shielding needs to be tailored for each unique device, which may involve multiple materials and layers of protection.

Interference from External Sources

Even with the best shielding materials, devices can still be susceptible to interference from external sources. Shielding effectiveness can be reduced by strong electromagnetic fields or poor design, leading to gaps where EMI can enter the device. Ensuring complete protection requires careful design and testing to identify and mitigate potential weak points.

Ensuring Long-Term Shielding Effectiveness

Over time, shielding materials can degrade due to environmental exposure, wear, and physical damage. Maintaining the effectiveness of shielding over the lifetime of a device is a challenge, particularly for devices that operate in harsh conditions. Regular maintenance and monitoring are essential to ensure that shielding remains effective throughout the device's life cycle.

To Sum Up

Effective electromagnetic shielding plays a crucial role in protecting sensitive electronics from the harmful effects of electromagnetic interference. By preventing external sources of interference from impacting a device's performance, shielding helps ensure that electronics operate reliably, accurately, and safely. The choice of shielding materials is critical to achieving the right balance of performance, cost, and durability, making it an important consideration for manufacturers across many industries.

As technology advances and devices become more complex, the need for specialized EM shielding will only grow. Innovations in materials and design will continue to shape the future of shielding, ensuring that electronic devices remain protected from interference and continue to deliver high performance in increasingly demanding environments.

In conclusion, electromagnetic shielding is a vital technology that safeguards the performance and reliability of electronic devices. Choosing the right materials and designing effective shielding systems are essential in ensuring that electronics continue to meet the ever-increasing demands of modern technology.

Need effective RF shielding materials for your electronics? Explore our range of RF absorbers designed to protect sensitive equipment from electromagnetic interference.

This article was written by the technical experts at dB Absorber, specializing in high-performance products for RF protection and electromagnetic compatibility.