NRL 8000 I, II and III Requirements

What are NRL 8000 I, II and III Requirements?

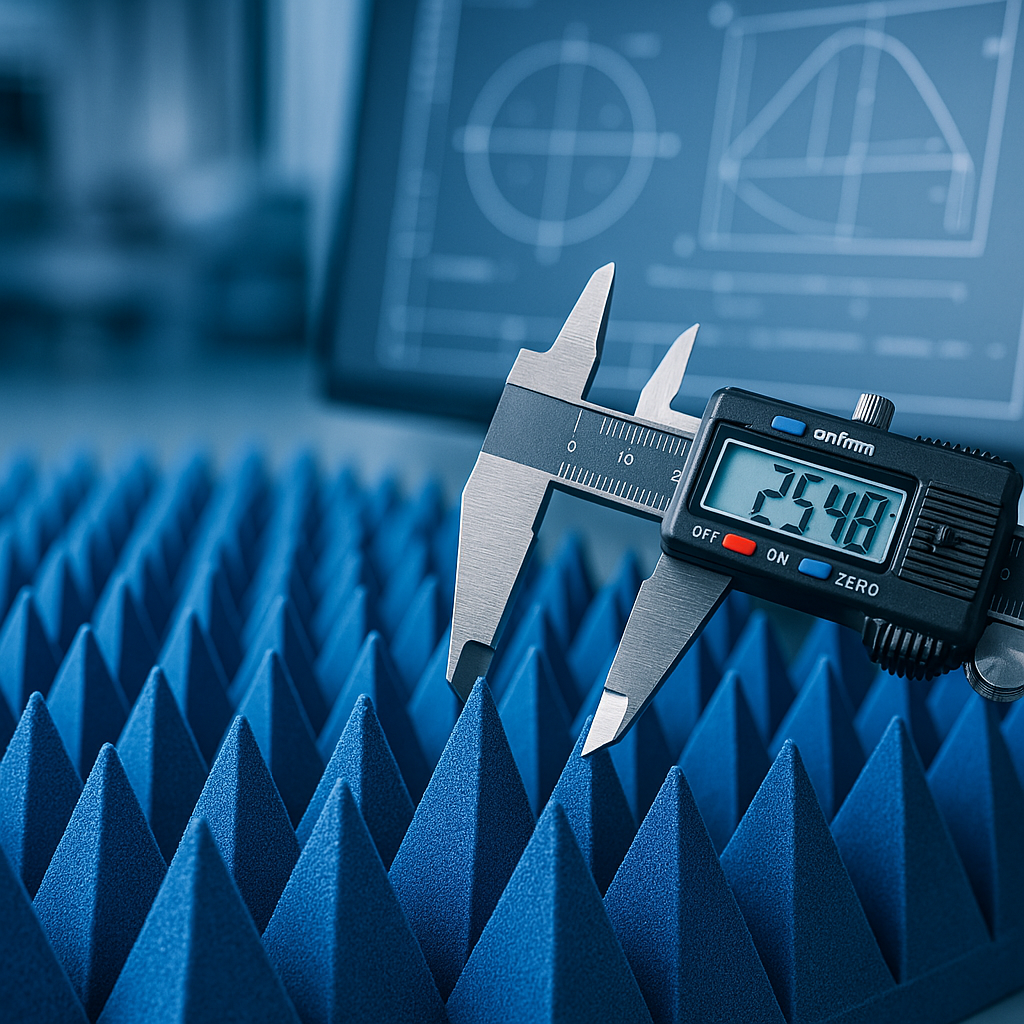

NRL 8000 I, II and III requirements are stringent fire safety and material standards established by the Naval Research Laboratory (NRL) for materials used in electromagnetic testing environments and anechoic chambers. These specifications define critical safety criteria for RF absorber materials, ensuring they meet strict fire resistance, smoke generation, and toxicity standards required for use in military, aerospace, and high-security testing facilities.

In simple terms, NRL 8000 requirements ensure that RF absorber materials are safe to use in enclosed testing environments where fire hazards could pose serious risks to personnel and equipment. Unlike standard commercial fire ratings, NRL 8000 standards address the unique challenges of electromagnetic testing facilities where large volumes of foam-based absorber materials are used in confined spaces.

How Do NRL 8000 Requirements Work?

NRL 8000 requirements operate through a comprehensive testing protocol that evaluates materials across multiple fire safety criteria. Materials must undergo rigorous testing to demonstrate their performance under controlled fire conditions, measuring factors such as ignition resistance, flame spread rates, heat release characteristics, smoke production, and toxic gas emissions. Only materials that pass all specified tests can be certified as meeting NRL 8000 standards.

For example, when an RF absorber material is tested under NRL 8000 protocols, it must demonstrate that it will not contribute to rapid fire spread in an anechoic chamber environment. The material is subjected to standardized flame exposure while instruments measure how quickly flames propagate, how much heat is released, and what types of gases are produced during combustion.

NRL 8000 Classification Levels

NRL 8000 I (Level I): The basic classification level that establishes fundamental fire safety requirements for RF absorber materials. Level I materials must demonstrate acceptable flame spread characteristics and heat release properties suitable for standard anechoic chamber applications where fire risk is moderate.

NRL 8000 II (Level II): An intermediate classification with enhanced fire safety requirements beyond Level I. Level II materials must exhibit improved flame resistance, reduced smoke generation, and lower toxic gas emissions, making them suitable for more critical testing environments or facilities with higher occupancy.

NRL 8000 III (Level III): The most stringent classification level requiring the highest fire safety performance. Level III materials must demonstrate superior flame resistance, minimal smoke production, and extremely low toxic gas emissions, qualifying them for use in the most critical military and aerospace testing facilities where maximum personnel safety is essential.

Key Features of NRL 8000 Standards

Multi-Level Classification System: NRL 8000 provides three distinct classification levels (I, II, and III) with progressively stringent requirements, allowing facility designers to select appropriate materials based on specific risk assessments and safety requirements.

Comprehensive Fire Safety Metrics: These standards evaluate multiple fire characteristics including ignition temperature, flame spread index, heat release rate, smoke density, and toxic gas generation, providing a complete safety profile for each material.

Reproducible Testing Protocols: NRL 8000 specifications define precise testing procedures and equipment requirements, ensuring consistent and reliable evaluation of materials across different laboratories and manufacturers.

Long-Term Performance Validation: The standards require materials to maintain their fire safety properties over extended periods and under various environmental conditions, ensuring continued safety throughout the material's service life.

Integration with Military Standards: NRL 8000 requirements align with broader military and defense specifications, ensuring compatibility with existing safety protocols in government and contractor facilities.

Benefits of NRL 8000 Compliance

NRL 8000 compliance provides facility operators with confidence that their RF absorber materials meet the highest fire safety standards, reducing risks to personnel and protecting valuable testing equipment in anechoic chambers and electromagnetic testing facilities.

With standardized testing protocols, NRL 8000 compliance enables consistent material selection across multiple facilities and projects, ensuring that fire safety performance meets predictable criteria regardless of the specific manufacturer or installation location.

NRL 8000 certified materials enhance facility insurance and regulatory compliance by demonstrating adherence to recognized military-grade safety standards, potentially reducing insurance costs and simplifying regulatory approval processes for sensitive testing facilities.

Applications of NRL 8000 Requirements

Military Testing Facilities: NRL 8000 compliance is mandatory for RF absorber materials used in military anechoic chambers and electromagnetic testing facilities, ensuring personnel safety during classified testing operations.

Aerospace Testing Centers: Commercial and government aerospace facilities utilize NRL 8000 certified materials for satellite testing, antenna measurements, and electromagnetic compatibility verification of flight systems.

High-Security Research Facilities: Government contractors and research institutions require NRL 8000 compliance for materials used in sensitive electromagnetic testing environments where safety and security are paramount.

Critical Infrastructure Testing: Facilities testing electromagnetic systems for power grids, telecommunications infrastructure, and other critical systems rely on NRL 8000 certified materials to ensure safe testing operations.

NRL 8000 I, II and III requirements represent the gold standard for fire safety in electromagnetic testing environments, providing comprehensive protection for personnel and equipment in anechoic chambers and RF testing facilities. By establishing rigorous testing protocols and performance criteria, these standards ensure that RF absorber materials maintain the highest safety standards while delivering the electromagnetic performance required for critical testing applications across defense, aerospace, and telecommunications industries.

Related: Explore our RF absorber products or read more on our technology blog.