Anechoic Chamber Design: Key Considerations for RF Testing Environments

An anechoic absorptive chamber is a controlled environment that simulates free-space conditions for accurate measurements and testing. This article provides a comprehensive guide to the key considerations in designing an absorptive chamber for RF testing environments, ensuring optimal performance, accurate results, and long-term functionality.

Whether you're involved in telecommunications, aerospace, automotive, or any other industry requiring precise RF measurements, understanding the design principles of an anechoic chamber is essential for effective testing.

What is an Anechoic Chamber?

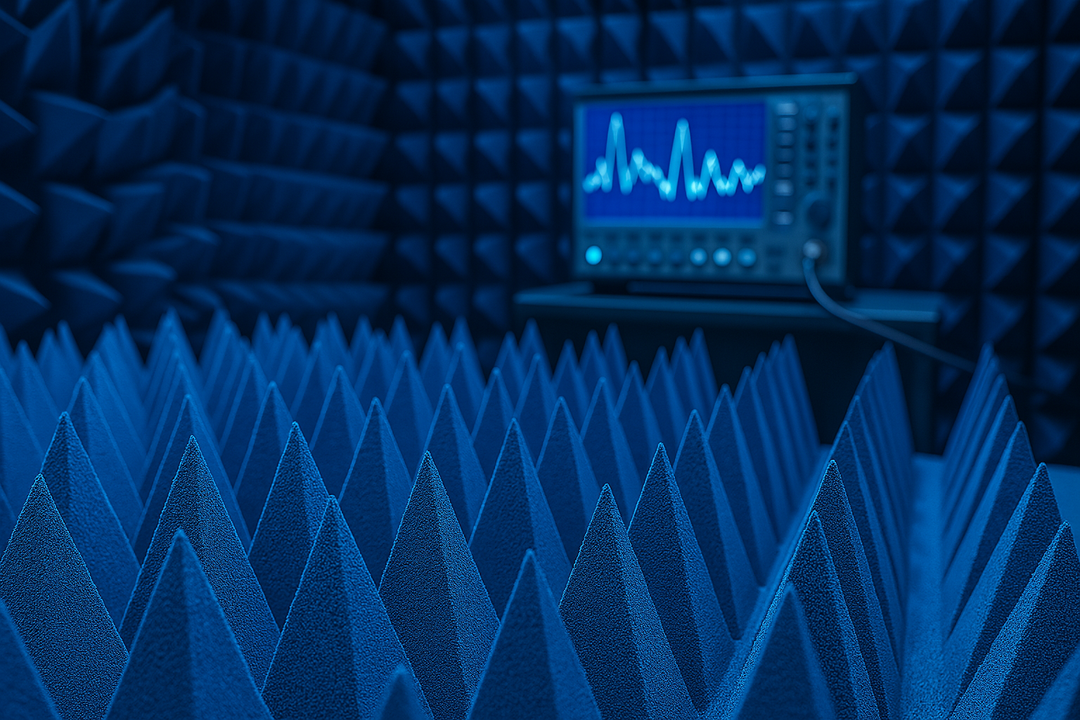

An anechoic non-reflective chamber is a specially designed room that isolates electromagnetic energy, ensuring no external signals interfere with testing. It is a space where sound, radio waves, or microwaves are absorbed, preventing any reflections that could distort measurements. These chambers are constructed to be as "quiet" as possible, meaning they absorb energy from all directions, mimicking an environment similar to free space.

The primary purpose of an anechoic chamber is to facilitate precise and accurate testing of various RF components, including antennas, radar systems, and wireless devices. Accurate measurements are vital for the development and certification of communication systems.

In telecommunications, aerospace, and automotive industries, anechoic rooms ensure that devices are tested under controlled conditions, free from any interference or noise that could compromise the results. Without such environments, conducting reliable tests would be nearly impossible.

Understanding the Basics of Anechoic Chambers

How Anechoic Absorptive Chambers Work

The key feature of an anechoic room is its ability to absorb incoming electromagnetic waves. These chambers typically feature surfaces covered with specialized absorber materials that prevent reflections from returning to the room.

The most common absorber materials are:

- Carbon-loaded foams

- Pyramidal absorbers

- Wedge-shaped absorbers

These materials are carefully arranged on the chamber's walls, ceiling, and floor to effectively absorb energy from all directions.

Absorptive chambers achieve their effectiveness by minimizing the interaction of electromagnetic waves with the room's surfaces. For example, the absorber materials, often pyramidal, are strategically positioned to gradually absorb RF signals as they are incident on the material from varying angles.

Some absorptive chambers are designed to control sound waves in addition to RF absorption, which is why they are also referred to as acoustic chambers. These chambers aim to absorb sound and electromagnetic radiation, providing a dual purpose in testing environments where sound control and RF isolation are necessary.

Types of Anechoic Chambers

There are different types of anechoic rooms designed for specific testing needs. Generally, chambers can be classified as:

Full Anechoic: Completely lined with absorbing materials, ensuring no reflections from any surface. They are used for the most demanding RF tests where precise and isolated measurement conditions are required.

Semi-anechoic: This design has absorbing materials on the walls and ceiling and a reflective floor. It is often used when testing requires a controlled environment, but some reflections are permissible.

Choosing the correct type of anechoic chamber room depends on the specific testing requirements, including the frequency range of the signals to be measured and the level of precision required.

Key Design Considerations for Anechoic Rooms

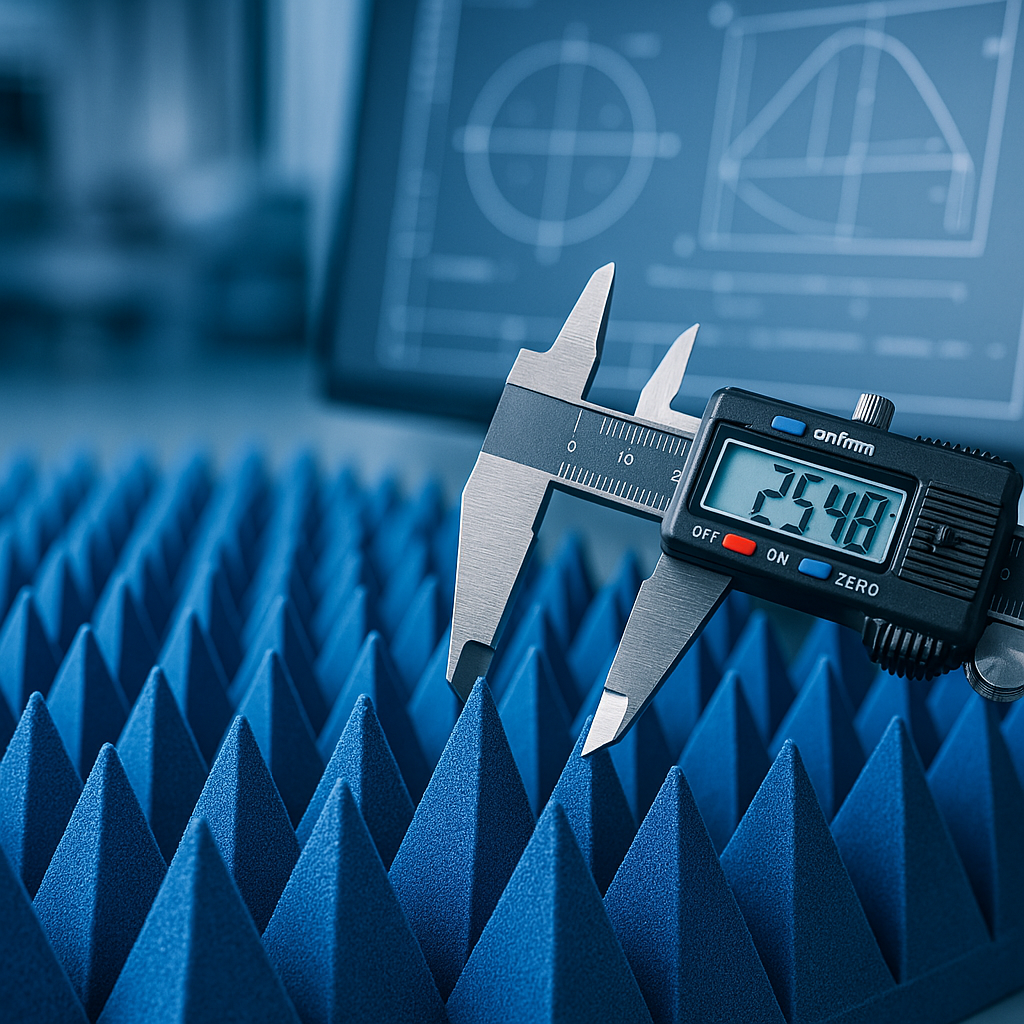

Absorber Materials and Configuration

One of the most critical aspects of anechoic noise-free room design is the selection of absorber materials. The absorbers must efficiently absorb electromagnetic waves and prevent any reflection. Common materials used in anechoic rooms include carbon-loaded foams, ferrites, and pyramidal absorbers, each with unique properties suited for different frequency ranges.

The configuration of these absorbers within the room is equally important. Absorber placement should minimize reflection while optimizing the chamber's performance. For instance, absorbers should be placed along walls, floors, and ceilings. Still, the height and angle of certain absorbers may need to be adjusted based on the chamber's intended use.

Room Dimensions and Geometry

The dimensions and geometry of an anechoic chamber are critical in ensuring that it meets the required testing specifications. A chamber that is too small may not provide enough space to properly isolate and absorb electromagnetic waves. At the same time, an oversized room could be inefficient, leading to increased costs and energy consumption.

When designing an anechoic room, the size must be based on the type of tests to be conducted. For example, testing large equipment like antennas or radar systems requires a larger room to ensure the device can be positioned correctly from the absorbers. In contrast, testing smaller devices may need less space, but the chamber must still be large enough for precise measurements.

Placement and Layout of Absorbers

The arrangement of absorbers within the room is essential to achieving optimal performance. Pyramidal absorbers, for example, must be placed strategically to maximize absorption efficiency, especially for higher-frequency tests. The layout should be designed to ensure that electromagnetic waves are absorbed from all directions, leaving no space for unwanted reflections.

Additionally, the layout must allow easy access to the device under test (DUT) while ensuring that the absorbers do not obstruct critical testing areas.

Electromagnetic Shielding and Isolation

Electromagnetic shielding is another critical consideration in anechoic chamber design. The chamber must be completely isolated from external RF interference to ensure no unwanted signals affect the test. This requires high-quality shielding materials such as metal enclosures or specialized coatings to block external RF signals.

Proper grounding and isolation of the chamber's door, windows, and other openings are equally important. Any gaps in the shielding can introduce interference, compromising the chamber's performance.

Acoustic Considerations in Anechoic Chamber Design

While the primary focus of an anechoic room is RF absorption, many chambers also need to manage sound. In industries such as aerospace or automotive, testing systems often need to be assessed for their electromagnetic and acoustic performance. Balancing the absorption of sound and electromagnetic waves within a single chamber requires careful consideration of the chamber's design and the materials used.

The need to control sound reflections in an acoustic anechoic chamber can significantly impact RF testing. For instance, soundproofing the room while maintaining effective RF absorption demands a thoughtful approach. Rooms must be designed with materials that absorb sound and prevent RF waves from being reflected into the test area.

Testing and Calibration of Anechoic Rooms

To ensure that an anechoic room provides accurate and reliable results, it must adhere to strict standards for RF testing accuracy. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) set the benchmarks for chamber performance. These standards ensure that the chamber meets the specifications for frequency range, absorption efficiency, and shielding effectiveness.

An anechoic chamber requires regular maintenance and calibration to ensure that it continues to perform at optimal levels. Absorber materials can degrade over time, especially if exposed to high levels of electromagnetic energy. Regular inspection and replacement of worn-out absorbers are necessary to maintain performance. Performance evaluation tests should also be conducted periodically to verify that the chamber meets all relevant standards.

Challenges in Anechoic Chamber Design

Dealing with High-Frequency RF Signals

Managing high-frequency RF signals is one of the biggest challenges in anechoic room design. As the frequency increases, the wavelength becomes smaller, requiring more precise absorber configurations. It makes designing a chamber for high-frequency RF testing more complex and costly, but it's essential for industries such as telecommunications and aerospace that rely on high-frequency RF systems.

Space and Cost Constraints

Designing an absorptive chamber that meets all of the necessary requirements for RF testing can be expensive, especially for large chambers with specialized absorber materials. Cost considerations must be balanced with performance needs to ensure the chamber delivers accurate results without exceeding budget constraints.

Environmental Considerations

Environmental factors such as temperature, humidity, and airflow can all affect the performance of an anechoic chamber. Extreme temperature changes can cause absorber materials to degrade, while excess humidity can interfere with RF performance. Ensuring the chamber maintains a stable environment is key to achieving reliable and consistent test results.

Recap of Key Design Considerations

In summary, the design of an anechoic room requires careful attention to detail. From selecting the right absorber materials to ensuring proper shielding and room dimensions, every chamber aspect must be tailored to meet the specific testing requirements. Regular maintenance and calibration are essential to maintaining optimal performance, and future advancements in materials and technology will continue to improve anechoic room design.

Future Trends in Anechoic Chamber Design

As technology advances, anechoic rooms will continue to evolve with advancements in materials science. New, more efficient absorber materials and improved design techniques will enable more compact and cost-effective chambers. Additionally, as wireless communication technologies such as 5G become more widespread, the need for more advanced and adaptable anechoic rooms will grow. It will drive innovation in chamber design, making it possible to test new technologies with even greater precision.

Conclusion

Understanding the key considerations in anechoic chamber design is crucial for anyone involved in RF testing. From absorber materials to electromagnetic shielding, every design element plays a significant role in ensuring accurate results. As technology progresses, the future of absorptive chambers looks promising, with new materials and designs offering more efficient and effective testing environments.

Need high-quality RF absorbers for your anechoic chamber? Browse RF absorber products designed for optimal performance across a wide frequency range.

This article was written by the RF experts at dB Absorber, specializing in high-performance broadband anechoic absorbers for RF and microwave applications.